Manufacturing Facility

Facilities

Glimpse of BRAVIX Facility

The BRAVIX AAC block manufacturing facility is equipped with advanced automation, precision cutting technology, and autoclave curing systems. It ensures consistent quality, high compressive strength, and eco-friendly production. Designed for scalability and speed, the plant supports sustainable construction by delivering lightweight, durable AAC blocks ideal for modern infrastructure and smart building solutions.

Facility Footprint

sq. ft

Units Produced Daily

CBM

Manufacturing Process

Manufacturing Process of BRAVIX AAC Blocks

Raw Material Preparation

The journey begins with preparation of raw materials including sand, cement, lime, and water in the Batching Unit with an expansion agent (aluminum powder).

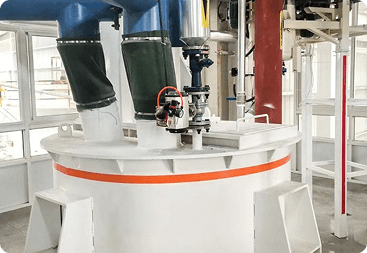

Mix Up

The raw materials are transferred to a high-speed mixer where they are thoroughly mixed to create a homogenous slurry.

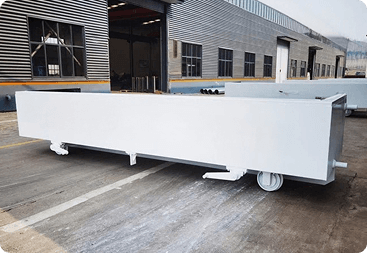

Even molding

The mixture is poured into the designated moulds to shape the blocks.

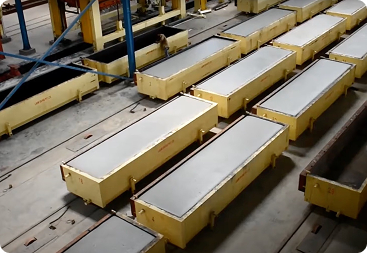

Precuring Stage

The molds are moved to a Precuring Chamber where the slurry undergoes an initial hardening phase – forming a cake.

Precision Cutting

Once the cake reaches the desired strength, it is removed from the mold and passed through a Cutting Machine for a uniform shape. Any waste material will be directed for reuse.

Autoclave Phase

The cut blocks undergo an Autoclave. Here, they are subjected to high-pressure steam curing at temperatures of around 180°C/190°C for continuous 8 to 12 hrs.

Quality Check

Performing rigorous inspections to ensure adherence to quality standards and specifications.

Adaptive Packaging

The cooled blocks are moved to the Packaging Unit where they are shrink-wrapped and stacked onto pallets for ease of handling.

Streamlined Distibution

The final product is then transported to the storage yard or directly loaded onto trucks for shipping to the respected construction sites.

QEHS

QEHS - Quality, Environmental, Health & Safety

At BRAVIX Private Limited, our commitment to QEHS (Quality, Environmental, Health, and Safety) drives every aspect of our operations. We adhere to rigorous global standards to ensure sustainable manufacturing, a safe working environment, and unmatched product quality. Through continuous improvement and responsible practices, we aim to lead the AAC block industry with integrity and innovation.